I spoke with Emma about slip casting because I know she uses the technique in her own practice. I had slip cast a small bowl for a test, and had some questions about the process.

One of the problems with my test was that after demoulding the bowl, the edges of the bowl tended to sag and the bottom that it was resting on flattened out. Emma suggested that I leave the clay to dry inside the plaster mould. I will need to do a test with a dryer plaster mould, because my first one was very wet and I don't imagine the clay would have dried very fast inside it. Another way to stop it deforming is to use a two part mould, where the second part is a ring that covers the top edges of the bowl. This creates a supportive structure that can be trimmed off when the clay is dry.

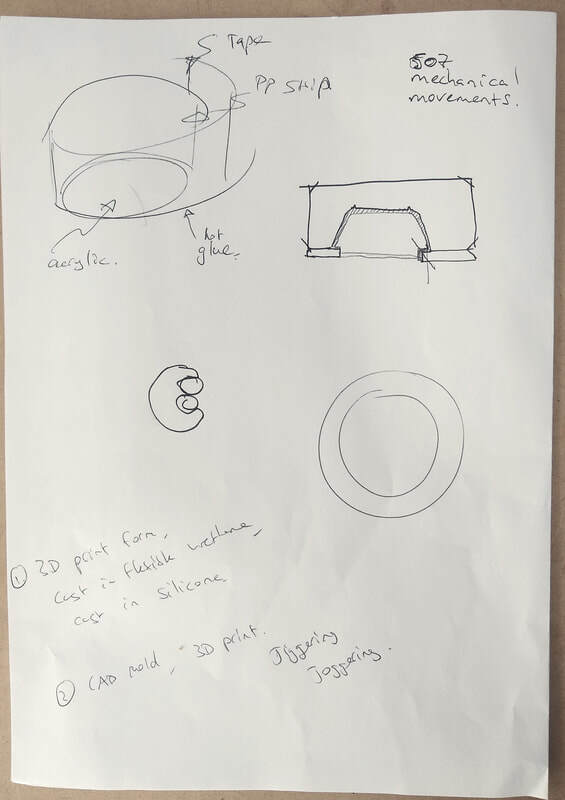

Emma suggested a different technique for making the plaster mould. For my test, I made a square mould in a wooden box. To use less plaster and have a lighter mould that is quicker to dry, I should make a round mould. Emma uses a laser cut acrylic circle as a base, wraps a PP strip around it to make a wall for the plaster, uses packing tape to secure the PP to itself, and hot glues the outside of the PP where it meets the table, ensuring there is no leakage.

I asked Emma for suggestions on how I could make a groove in the surface of the bowl around its circumference. The groove would hold the edge of an elasticated cover. She said I could make it in the mould, or cut it after (which would probably be easier). There are two ways to make it in the mould: 3D print the form, cast it in flexible urethane, cast silicone into the urethan mould, and then use the silicone form to build the plaster mould (silicone is stretchy so it can be manoeuvred out of the plaster mould once dry); or CAD the mould, 3D print it and cast into that with silicone.

Emma also suggested I look up jiggering and jollying techniques for ceramics.